SLA 3D Printing Support Generating

Developed a C++ library to generate the support structure for SLA 3D printing. This is a industry collaboration project with Young Optics inc.

What is SLA 3D printing?

SLA (Stereolithography) technology uses photopolymer resin as raw material, solidifying liquid resin through UV light exposure. The difference from common FDM technology is that this printing technique can produce models with higher resolution, and the surface layer patterns of the results are less visible. It is commonly used for model making, dental materials, and other model production that requires high detail representation.

→ More information about SLA 3D printing.

→ More information about FDM 3D printing.

What is support structure in 3D printing?

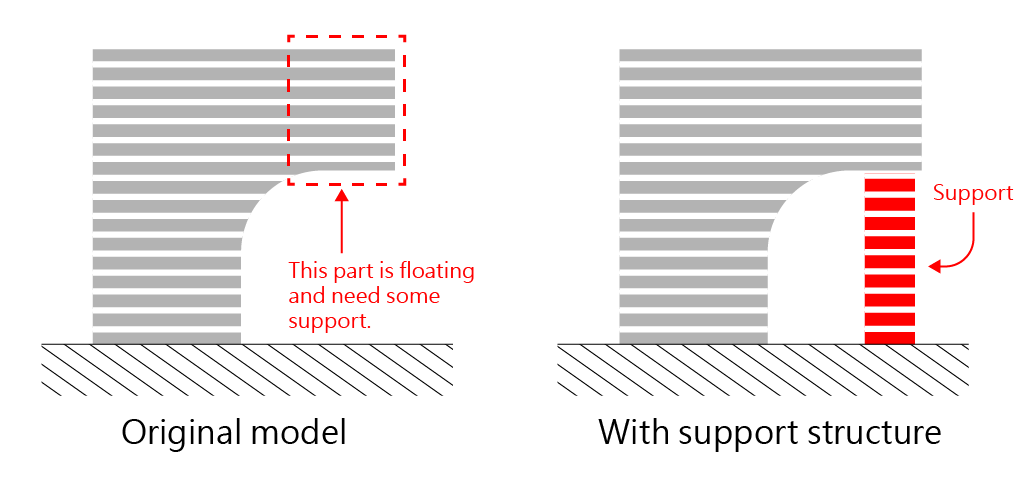

Due to the layer-by-layer nature of 3D printing, when printed objects have overhangs, bridges, or suspended parts, these structures require additional support structures from below, otherwise they would collapse or deform during the printing process. These support structures are typically generated by automated processes and are designed to be easily removed from the main model. After printing is complete, users need to manually remove the support material using tools.

Due to the layer-by-layer nature of 3D printing, when printed objects have overhangs, bridges, or suspended parts, these structures require additional support structures from below, otherwise they would collapse or deform during the printing process. These support structures are typically generated by automated processes and are designed to be easily removed from the main model. After printing is complete, users need to manually remove the support material using tools.

→ More information about support structure.

What are the difficulties of generating support structure for SLA 3D printing?

- Accurate identification of overhanging structures

Accurately determining which areas need support is not always intuitive, especially for complex geometric shapes. - Optimal support point distribution

Determining the optimal position and density of support points to ensure structural stability without excessive material usage. - Self-supporting angle determination

Different materials and printing parameters have different self-supporting angles, requiring precise calculation of critical angles. - Tree-like support generation

Tree-like supports are usually used in SLA 3D printing. Efficient tree-like supports are more complex than simple grid supports (are usually used in FDM), requiring consideration of mechanical balance and branching strategies. - Multi-directional support strategies

For some complex shapes, support may be needed from multiple directions.

Result of this project

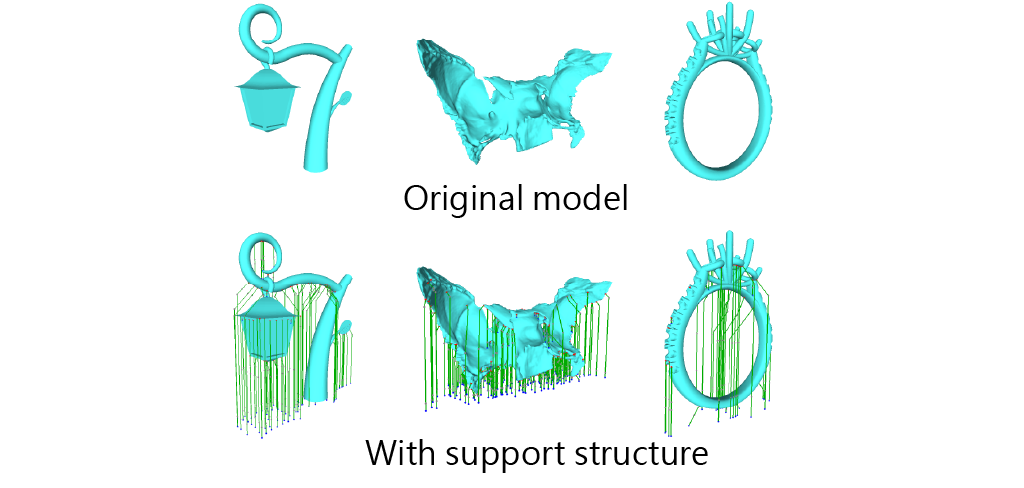

This figure shows the support structures generated by the library I developed. You can see that support structure has been properly generated for the floating areas on the complex model. Additionally, parameters such as support structure density, support direction, and number of branches can all be adjusted.

This figure shows the support structures generated by the library I developed. You can see that support structure has been properly generated for the floating areas on the complex model. Additionally, parameters such as support structure density, support direction, and number of branches can all be adjusted.